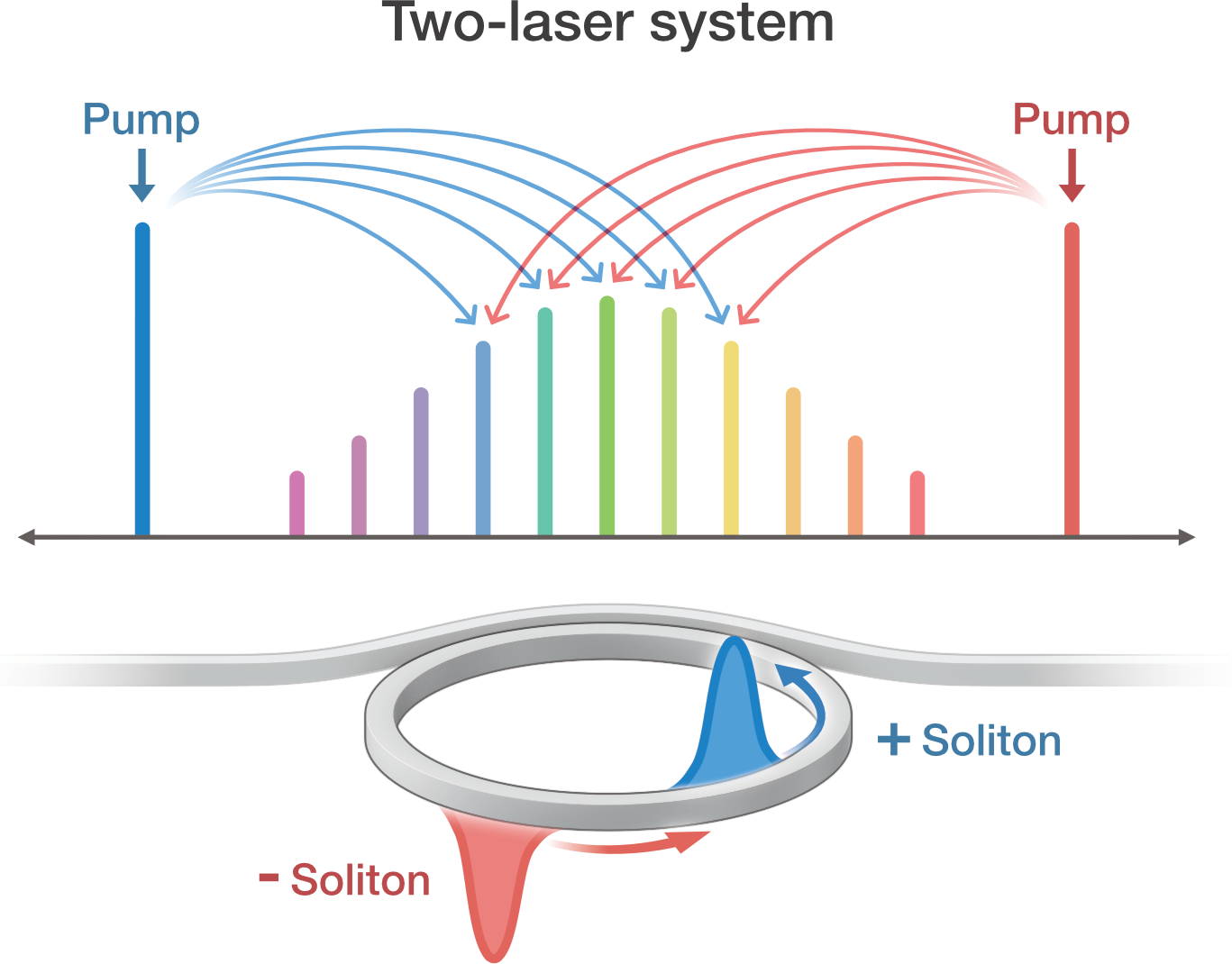

Top: In the new comb system, two pump lasers shape each tooth, producing a frequency comb that could theoretically be sharper than a comb produced by a single laser. Bottom: The interaction between the two lasers randomly produces solitons in two different phases, which can be understood as a soliton pulse having either a positive or negative sign.Credit: S. Kelley/NIST

A frequency comb acts as a ruler for light. Just as the uniformly-spaced tick marks on an ordinary ruler measure the length of objects, the uniformly-spaced frequency spikes on a microcomb measure the oscillations, or frequencies, of light waves.

Researchers typically employ three elements to build a microcomb: a single laser, known as the pump laser; a tiny ring-shaped resonator, the most important element; and a miniature waveguide that transports light between the two. Laser light that’s injected into the waveguide enters the resonator and races around the ring. By carefully adjusting the frequency of the laser, the light within the ring can become a soliton—a solitary wave pulse that preserves its shape as it moves.

Each time the soliton completes one round trip around the ring, a portion of the pulse splits off and enters the waveguide. Soon, an entire train of the narrow pulses, which resemble spikes, fills the waveguide, with each spike separated in time by the same fixed interval—the time it took for the soliton to complete one lap. The spikes correspond to a single set of evenly spaced frequencies and form the tick marks, or “teeth,” of the frequency comb.

This method of generating a microcomb, though effective, can only produce combs with a range of frequencies centered on the frequency of the pump laser. To overcome that limitation, NIST researchers Grégory Moille and Kartik Srinivasan, working with an international team of researchers led by Miro Erkintalo of the University of Auckland in New Zealand and the Dodd-Walls Centre for Photonic and Quantum Technologies, theoretically predicted and then experimentally demonstrated a new process for producing a soliton microcomb. Instead of employing a single laser, the new method uses two pump lasers, each of which emits light at a different frequency. The complex interaction between the two frequencies produces a soliton whose central frequency lies exactly in between the two laser colors.

The method allows scientists to generate combs with novel properties in a frequency range that is no longer limited by pump lasers. By generating combs that span a different set of frequencies than the injected pump laser, the devices could, for example, allow scientists to study the composition of biological compounds.

Beyond this practical advantage, the physics that underlies this new type of microcomb, known as a parametrically-driven microcomb, may lead to other important advances. One example is a potential improvement in the noise associated with the individual teeth of the microcomb.

In a comb generated by a single laser, the pump laser directly sculpts only the central tooth. As a result, the teeth become wider the farther they lie from the center of the comb. That’s not desirable, because wider teeth can’t measure frequencies as precisely as narrower ones.

In the new comb system, the two pump lasers shape each tooth. According to theory, that should produce a set of teeth that are all equally narrow, improving the accuracy of measurements. The researchers are now testing whether this theoretical prediction holds true for the microcombs they have fabricated.

The two-laser system offers another potential advantage: It produces solitons that come in two varieties, which can be likened to having either a positive or negative sign. Whether a particular soliton is negative or positive is purely random because it arises from the quantum properties of the interaction between the two lasers. This may enable the solitons to form a perfect random number generator, which plays a key role in creating secure cryptographic codes and in solving some statistical and quantum problems that would otherwise be impossible to solve with an ordinary, non-quantum computer.

The researchers described their work online in the March 14 issue of Nature Photonics. The team includes François Leo and his colleagues from the Université Libre de Bruxelles, Belgium, Julien Fatome of the Université de Bourgogne in Dijon, France, and scientists from the Joint Quantum Institute, a research partnership between NIST and the University of Maryland.

Provided by National Institute of Standards and Technology